Release time:2024-10-10

![]()

|  |  |

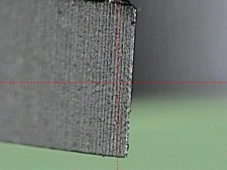

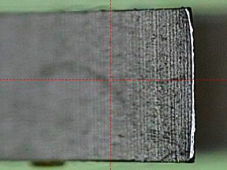

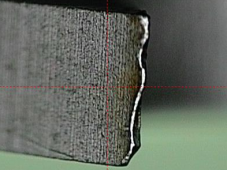

| Before break-in | After proper break-in | After improper break-in |

Tooth tips are very sharp and sometimes with some small burs from manufacturing. | Proper break-in makes blades gain a good tooth tip with small round cutting edge,which is beneficial for prolonging blade life. | Improper break-in results in disastrous chipping on tooth tips,which shortens blade life greatly. |

For bi-metal bandsaw blade:

1) Use the recommended band speed for the material you want to cut.

2) Reduce the feed rate with 30-40%.

3) Run the blade for 30-60 min and slightly increase the feed with every cut.

4) Set band speed and feed rate as normal.

For carbide bandsaw blade:

1) For the 1st cut,set feed and band speed parameters as for a bimetal.

2) For the second cut increase band speed,while avoiding vibration.

3) Then increase feed to match band speed while avoiding vibration.

4) Repeat second cut till you have reached normal parameter values for a carbide blade.

Steel grade | dimensionφ (mm) | 100 | 200 | 300 | 400 | 500 | 700 | 1000 |

Carbon steel/ Low alloy steel | Band speed (m/min) | 50-85 | 50-75 | 45-65 | 40-50 | 35-45 | 30-40 | 25-35 |

Efficiency (cm²/min) | 45-70 | 50-80 | 45-65 | 35-50 | 35-45 | 25-35 | 20-30 | |

Cr alloy steel/ Cr-Mo steel/ Ni-Cr-Mo steel | Band speed (m/min) | 50-65 | 50-60 | 45-55 | 40-50 | 35-45 | 30-40 | 20-30 |

Efficiency (cm²/min) | 30-50 | 40-48 | 35-42 | 30-40 | 28-36 | 22-32 | 16-25 | |

Mold steel/ Hot-work steel/ Cold-work steel/ Tool steel | Band speed (m/min) | 24-40 | 24-40 | 22-40 | 20-35 | 20-35 | 18-30 | 16-25 |

Efficiency (cm²/min) | 8-20 | 16-30 | 14-30 | 12-28 | 12-28 | 10-25 | 8-18 | |

Stainless steel | Band speed (m/min) | 40-50 | 35-45 | 35-40 | 28-35 | 25-32 | 20-28 | 18-25 |

Efficiency (cm²/min) | 20-30 | 28-35 | 26-32 | 20-30 | 18-25 | 15-22 | 10-18 |

· The chart is only for materials with hardness of 20HRc or 225HB.When hardness ~30HRc or 283HB,slow the speed to 70% of the recommended in the chart.

When hardness ~35HRc or 330HB,slow the speed to 60% of the recommended in the chart.Bi-metal is not suggestible for workpiece with hardness higher than 40HRc.

· Actually,bandsawing parameter is strongly affected by external factors like machine condition,materials,fluid,etc.So your experience is very important.

Steel grade | dimensionφ (mm) | 100 | 200 | 300 | 400 | 500 | 700 | 1000 |

Hard wood | Band speed (m/min) | 1200-1500 | 1200-1500 | 1200-1500 | 1200-1500 | 1200-1500 | ||

Efficiency (cm²/min) | 6500-7200 | 1800-2000 | 1800-2000 | 1500-1600 | 1500-1600 | |||

Aluminum alloy | Band speed (m/min) | 1200-1500 | 1500-2000 | 1500-2000 | 2000-2500 | 2000-2500 | 2000-2500 | 2000-2500 |

Efficiency (cm²/min) | 1000-1200 | 1000-1200 | 1000-1200 | 1400-1800 | 1400-1800 | 1400-1800 | 1400-1800 | |

Stainless steel | Band speed (m/min) | 25-30 | 25-30 | 25-30 | 25-30 | 25-30 | 25-30 | |

Efficiency (cm²/min) | 5.0-6.0 | 5.0-6.0 | 5.0-6.0 | 4.5-5.5 | 4.5-5.5 | 4.5-5.5 | ||

Case-hardened steel | Band speed (m/min) | 40-50 | 40-50 | 35-45 | 35-45 | 35-45 | ||

Efficiency (cm²/min) | 10-15 | 10-15 | 10-15 | 10-15 | 10-15 | |||

Titanium alloy | Band speed (m/min) | 30~45 | 30~45 | 30~40 | 30~40 | 25~35 | 25~30 | 20~25 |

Efficiency (cm²/min) | 14-18 | 14-18 | 14-18 | 12-16 | 12-16 | 10-14 | 10-14 | |

Superalloy | Band speed (m/min) | 25-30 | 25-30 | 20-25 | 20-25 | 20-25 | 20-25 | |

Efficiency (cm²/min) | 3.5-8 | 3.5-8 | 3.5-7 | 3.5-7 | 3.5-6 | 3.5-6 |